News

The Application of Primary Filters in the Automobile Painting Industry

Time:2024-01-11

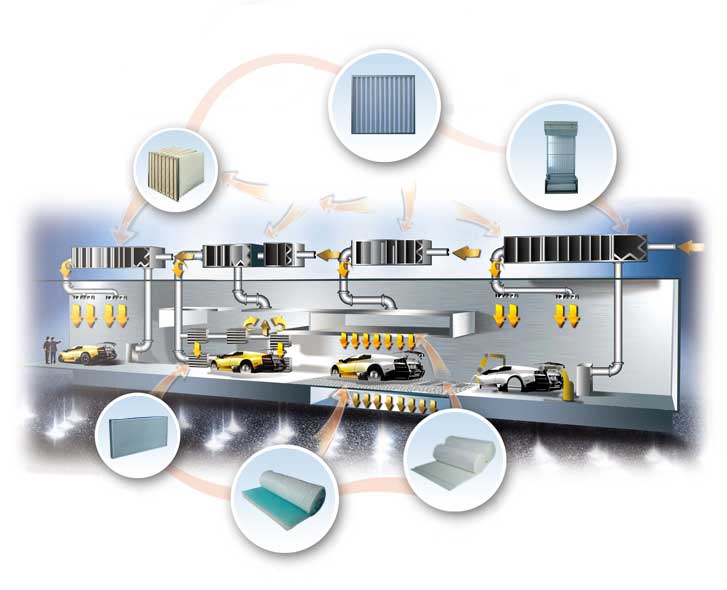

In the automobile painting industry, ensuring a clean and contaminant-free environment is essential for the production of high-quality and durable paint finishes. One key component in achieving this is the use of primary filters. These filters play a crucial role in removing dust, dirt, and other particulate matter from the air before it enters the painting booth.

Primary filters are specifically designed to trap larger particles that are carried in the air, preventing them from settling on the painted surfaces. By removing these particles early in the air filtration process, the filters help to maintain a clear and even coat of paint, resulting in a more consistent and defect-free finish.

In addition to particle removal, primary filters also contribute to the overall efficiency of the painting process. By ensuring a steady supply of clean air to the painting booth, the filters prevent equipment clogging and fouling, which can lead to downtime and increased maintenance costs. This maintains consistent paint application and promotes a faster drying process, resulting in increased productivity and reduced production costs.

Furthermore, primary filters contribute to the safety of both the operators and the painted vehicles. By trapping potentially harmful particles before they reach the paint booth, the filters minimize the risk of respiratory irritation and other health hazards associated with exposure to contaminated air. This ensures a safer working environment for those involved in the painting process.

We can provide products such as high-temperature resistant partition filters, high dust capacity primary and medium efficiency bag filters, paint mist felt, high-temperature resistant filter cotton, automatic winding filters, etc. These products do not contain silicone and have high temperature resistance, which can meet the special requirements of the coating industry.